SC-7099

Scince

Functions

It is used for the performance test of air filters, including class M5 to class H14 filter products. Panel filter, V-bank filter, filter bag and cylinder filter can be tested.

The test results include overall efficiency @0.3μm, @0.5μm, ePM1.0, ePM2.5, resistance, air flow - resistance curve, etc.

If the dust generator, dust feeder, and other components are selected, dust capacity test, arrestance (gravimetric efficiency) VS dust load, resistance VS dust load, efficiency@0.4 μm VS dust load and fractional efficiency VS different final resistance can be realized.

Equipped with SC-189, the following indexes can also be tested: dust holding capacity, arrestance, pressure drop vs. dust load, arrestance vs. dust load, etc,.

Advantages

The filter efficiency test range is wide, select test mode, the test concentration is adjusted automatically, save workload.

Adopted the main control board and upper computer software system to ensure the stability of the control system.

Adopted advanced on-line monitoring software system. Test parameters, process and results are reflected on the computer LCD display.

The start and stop of the aerosol generator, the conversion of the upstream and downstream laser particle counter, and inflation and sealing all are automatically controlled by the corresponding solenoid valves.

The test system adopts positive pressure, sets the air volume through software, and uses the frequency converter to realize automatic control of air volume.

The test results are automatically generated into reports, print as A4 report or self-adhesive label.

The system uses a bypass diluter with large dilution ratio and reliability.

It can monitor the compressed air pressure in real time, and the system will automatically prompt when the pressure is insufficient or overpressure.

It can automatically monitor the resistance of inlet air filter and set automatic replacement reminder.

It is especially suitable for the filter production manufacturers, with high stability, suitable for long-term continuous use, and low maintenance and use costs.

Technical parameters

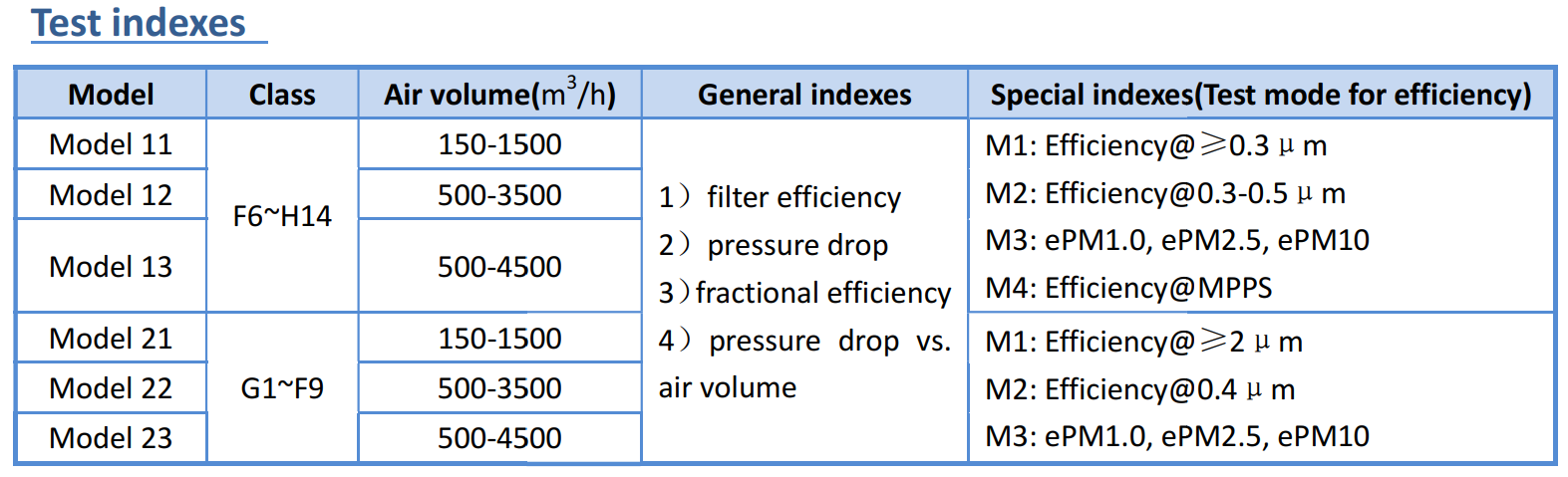

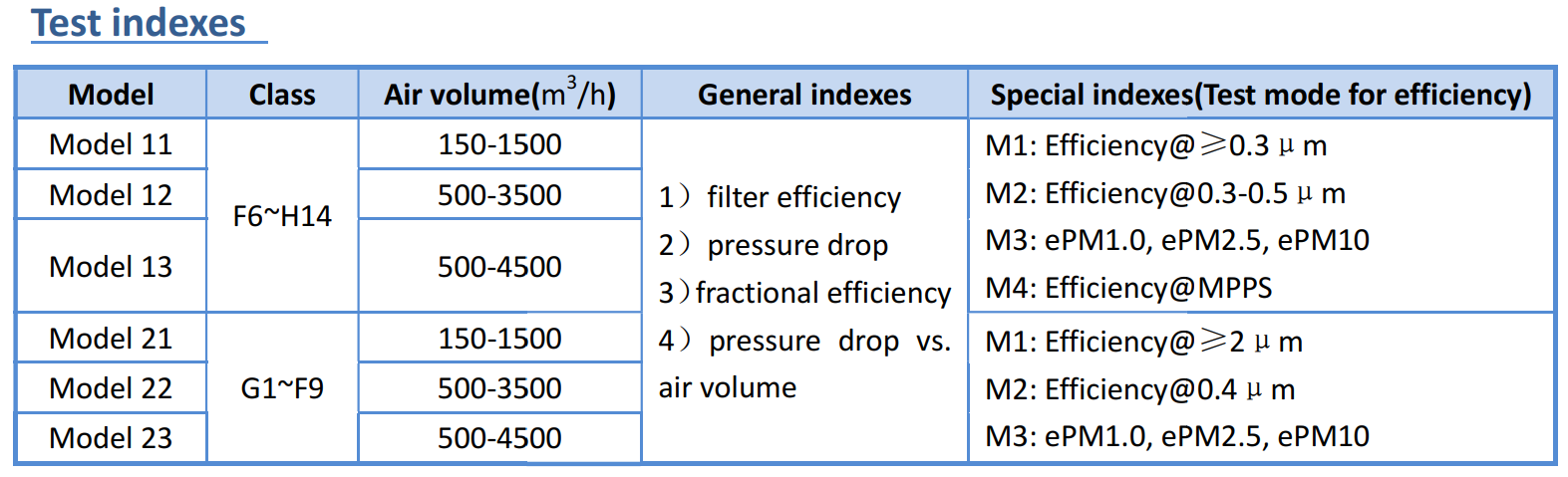

1. Output air volume:

The conventional model is150-1500m3 / h.

At the same time, the product has different configurations, which can be used to meet the selection of different test air volume ranges. The minimum air volume 50 m3 / h and the maximum air volume can reach 4500 m3 / h.

2. Pressure range: 0~500Pa, accuracy 1%.

3. Particle size: ≥0.3μm.

4. Aerosol: DEHS.

5. Sampling flow: 6 channels, 0.3, 0.5, 1.0, 3.0, 5.0, 10.0μm.

6. Filter efficiency range: 45%~99.995%@0.3μm.

7. Maximum size of the filter can be tested:

Flat filter and W-type filter: 745mm × 610mm × 350mm.

Bag filter: 750mm × 610mm × 300mm(air volume 1500 m3 / h), 750mm × 610mm ×740mm(air volume 4500 m3 / h).

Cylinder filter: φ455mm×350mm (air volume 1500 m3 / h), φ455mm×800mm (air volume 4500 m3 / h).

If you need to test wider or thicker filters, we can provide customized services.

8. Dimensions:

SC-7099-1500: 3350mm×1800mm×1900mm;

SC-7099-4500: 4500mm×1900mm×1900mm;

The equipment size will vary with the air volume range.

Working conditions

1. Voltage: AC 380V,50Hz.

2. Power: 2500W (SC-7099-1500), 5000W (SC-7099-4500).

3. Temperature: ( 23 ± 5) ° C.

4. Relative humidity: (20~70)%RH.

5. Gas supply: 5~8kg/ cm2.

Functions

It is used for the performance test of air filters, including class M5 to class H14 filter products. Panel filter, V-bank filter, filter bag and cylinder filter can be tested.

The test results include overall efficiency @0.3μm, @0.5μm, ePM1.0, ePM2.5, resistance, air flow - resistance curve, etc.

If the dust generator, dust feeder, and other components are selected, dust capacity test, arrestance (gravimetric efficiency) VS dust load, resistance VS dust load, efficiency@0.4 μm VS dust load and fractional efficiency VS different final resistance can be realized.

Equipped with SC-189, the following indexes can also be tested: dust holding capacity, arrestance, pressure drop vs. dust load, arrestance vs. dust load, etc,.

Advantages

The filter efficiency test range is wide, select test mode, the test concentration is adjusted automatically, save workload.

Adopted the main control board and upper computer software system to ensure the stability of the control system.

Adopted advanced on-line monitoring software system. Test parameters, process and results are reflected on the computer LCD display.

The start and stop of the aerosol generator, the conversion of the upstream and downstream laser particle counter, and inflation and sealing all are automatically controlled by the corresponding solenoid valves.

The test system adopts positive pressure, sets the air volume through software, and uses the frequency converter to realize automatic control of air volume.

The test results are automatically generated into reports, print as A4 report or self-adhesive label.

The system uses a bypass diluter with large dilution ratio and reliability.

It can monitor the compressed air pressure in real time, and the system will automatically prompt when the pressure is insufficient or overpressure.

It can automatically monitor the resistance of inlet air filter and set automatic replacement reminder.

It is especially suitable for the filter production manufacturers, with high stability, suitable for long-term continuous use, and low maintenance and use costs.

Technical parameters

1. Output air volume:

The conventional model is150-1500m3 / h.

At the same time, the product has different configurations, which can be used to meet the selection of different test air volume ranges. The minimum air volume 50 m3 / h and the maximum air volume can reach 4500 m3 / h.

2. Pressure range: 0~500Pa, accuracy 1%.

3. Particle size: ≥0.3μm.

4. Aerosol: DEHS.

5. Sampling flow: 6 channels, 0.3, 0.5, 1.0, 3.0, 5.0, 10.0μm.

6. Filter efficiency range: 45%~99.995%@0.3μm.

7. Maximum size of the filter can be tested:

Flat filter and W-type filter: 745mm × 610mm × 350mm.

Bag filter: 750mm × 610mm × 300mm(air volume 1500 m3 / h), 750mm × 610mm ×740mm(air volume 4500 m3 / h).

Cylinder filter: φ455mm×350mm (air volume 1500 m3 / h), φ455mm×800mm (air volume 4500 m3 / h).

If you need to test wider or thicker filters, we can provide customized services.

8. Dimensions:

SC-7099-1500: 3350mm×1800mm×1900mm;

SC-7099-4500: 4500mm×1900mm×1900mm;

The equipment size will vary with the air volume range.

Working conditions

1. Voltage: AC 380V,50Hz.

2. Power: 2500W (SC-7099-1500), 5000W (SC-7099-4500).

3. Temperature: ( 23 ± 5) ° C.

4. Relative humidity: (20~70)%RH.

5. Gas supply: 5~8kg/ cm2.