Whether it is a clean room air conditioning system used in the biomedical, semiconductor, or electronics industries, or an HVAC system in an office building, airport, or station, or a central air conditioning system for home use, there is not a single class of filter used in the air filtration system, but a combination of multiple classes of filters.

The role of filters in air filtration systems

Pre-filters are usually used in clean room air conditioning systems before HEPA/ULPA filters. When excessive dust is collected on the HEPA filter, the pressure increases, and when it affects the normal air supply, the HEPA filter should be scrapped. Increasing the filter area of the HEPA filter or increasing the number of filters can extend the service life of the filter. But these practices have limited operating space, it is impossible to infinitely increase the filter area, to extend the service life of the high efficiency filter. The fundamental way is to block the dust by the pre-filter. Experienced owners prioritize the maintenance and investment in pre-filters, as their replacement typically does not cause production downtime or extensive commissioning. For Class 10,000 and 100,000 cleanrooms, pre-filters are available as F8 filters. For chip factory class 100, class 10 or higher clean room, the common efficiency level of pre-filter is H10 (85%@ MPPS), many new projects simply choose HEPA (efficiency ≥ 99.97%@0.3μm).

For HVAC systems and home air conditioning systems, filter replacement is relatively simple for both inlets and outlets, and no downtime is required. Before the COVID 2019 outbreak, many air outlets in public buildings were not equipped with filters and were generally made of metal such as aluminum. In the middle of the COVID 2019 outbreak, there was a case in a hotel that showed that people who were not infected with the virus became infected from exposure to the virus that spilled out of the ventilation ducts. Later, filters were added to the air outlets of many public buildings to filter particles, bacteria and viruses.

Filter media (filter materials) for different class filters

1) Coarse filtration materials

Coarse filtration materials include 100% synthetic fiber filter media (mostly PP), cleanable artificial fiber, activated carbon filter material, high temperature resistant glass fiber material, etc. It is used to filter particles, dust and various suspended matters above 5μm, and has the characteristics of large air volume, low pressure drop, high dust holding capacity and long service life.

Cleanable man-made fiber material, after cleaning the filter efficiency will be reduced, so it is also not recommended to use after repeated cleaning, generally cleaning 1 ~ 2 times after the need to do scrap disposal.

2) Medium efficiency filtration materials

Medium efficiency filter materials include chemical fiber, meltblown and ultra-fine glass fiber composites, glass fiber, etc. They are used to filter particles with particle size from 1 to 5μm, etc. They have the characteristics of large surface, high dust holding capacity and low air velocity.

Medium efficiency filter materials are usually distinguished by material color, F5 is earthy yellow, F6 is green, F7 is light pink, F8 is light yellow, and F9 is white.

3) HEPA/ULPA filter materials

HEEPA/ULPA filter materials are glass fiber, PTFE, nano materials, etc. In addition, the market of melt-blown non-woven fabric as mask filter material is saturated and the supply exceeds the demand, some companies turn to develop new uses of melt-blown non-woven fabric. One of them is used to make filters. High efficiency filter material is used to filter particulate matter, bacteria and viruses below 1μm. With high filtration efficiency, it is generally used as the last one of the air conditioning system, which is directly related to whether the clean room can reach the cleanliness.

The applications of filters of different classes made of different materials are somewhat specific. Usually, they are mainly used for filtering particulate matter, bacteria and viruses. When there is a filtration requirement for toxic gases or odors, it is necessary to use activated carbon filtration material, which has a better filtering effect on toxic gases and odors.

The role of filter media in air filtration systems

We learned about the role of air filter in air filtration system, and the filter media, as the most important component of air filter, has a great influence on filtration efficiency, resistance, the dust holding capacity and other indicators. Therefore, the filter media has an important role in the air filtration system, which affects whether the clean room cleanliness level is achieved, whether the air quality in public places is met, and the life of the whole air system, operation and maintenance costs, etc.

Therefore, the testing of filter materials is essential.

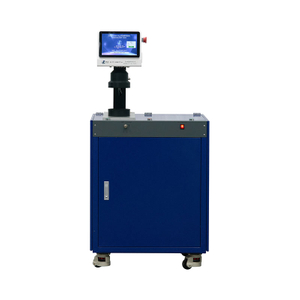

Our 1406D-Plus series filter media tester is divided into 4 models according to the class of filter material to be tested, and the models and the respective classes of material to be tested are shown in the table below. You can choose according to your needs.

Model | Filter efficiency | Filter media tested |

1406DL-Plus | 0~99%@0.3μm | Filter paper, filter cotton, etc. |

1406D-Plus | 45~99.99%@0.3μm | Melt-blown, fiber glass, etc. |

1406DH-Plus | 99~99.99995%0.3μm | Fiber glass, PTFE, nano fiber, etc |

1406DU-Plus | 99%~99.9999995%@0.1μm | Fiber glass, PTFE, nano fiber, HEPA/ULPA filter media |