English

Please Choose Your Language

- 한국어

- Türkçe

- English

- 简体中文

- 繁體中文

- العربية

- Русский

- Español

- Français

- Português

- Deutsch

- italiano

- 日本語

- Nederlands

- Tiếng Việt

- ไทย

- Polski

- አማርኛ

- ພາສາລາວ

- ភាសាខ្មែរ

- Bahasa Melayu

- ဗမာစာ

- தமிழ்

- Filipino

- Bahasa Indonesia

- magyar

- Română

- Čeština

- Монгол

- қазақ

- Српски

- हिन्दी

- فارسی

- Kiswahili

- Slovenčina

- Slovenščina

- Norsk

- Svenska

- українська

- Ελληνικά

- Suomi

- Հայերեն

- עברית

- Latine

- Dansk

- اردو

- Shqip

- বাংলা

- Hrvatski

- Afrikaans

- Gaeilge

- Eesti keel

- Māori

- All

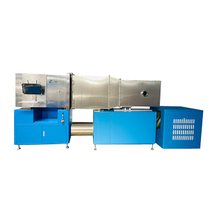

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search