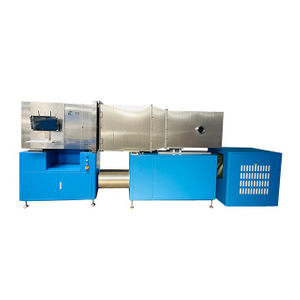

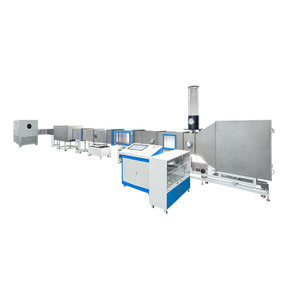

Operation

Using this equipment for filter testing requires very little work. Place the unit, press two buttons once, then test is running. The test time can be set by yourself, usually 30S. When you need quick detection, you can also adjust to 15S by yourself.

The pneumatic cylinder quickly presses the upper part of the clamp down to seal the filter and starts the test. After the test is finished, the fixture is automatically turned on and the test result is displayed on the touch screen automatically. Build-in thermal printer that prints test results.

Advantages

Microcomputer control, touch screen operation. The internal chip level design of the instrument, the micro control realizes the miniaturization of the instrument, and the touch screen realizes human-computer interaction. Intuitively display the test results, system status information and operation parameters, greatly reduce the amount of user training and improve the work efficiency.

Simple operation and maintenance free. The operation of the instrument is very simple, which reduces the technical level requirements for the instrument operators and greatly reduces the indirect use cost of the instrument. The instrument basically has no wearing and consumable parts and low maintenance cost.

Test results are automatically stored and printed. The touch screen displays the test results and contains the test conditions. The filter tester is equipped with a thermal printer, and the test results can be printed directly. It can be equipped with data acquisition software to edit and print the product quality report by computer. It can also print self-adhesive labels and paste them directly on the filter products.

For small filters with different shapes, customized fixtures can be provided.

It can be customized according to user needs. If fast detection is required, different configurations can be selected to realize 10s fast detection.If online detection is required, automatic feeding device can be selected.

Applications

Product development and quality inspection for production of vacuum cleaner filter unit.

Product development and quality inspection for the production of filter products for garden machinery.

Product development and quality inspection for the production of HEPA filters for printers, precision instruments, medical devices, etc.

Technical parameters

1.Test air volume: 50~120m3/h; (can be customized according to customer needs)

2.Test area: 100cm2(customize different fixture for different shape filters up to 200*200mm)

3.Test resistance range: 0~500Pa; (can be customized according to customer needs)

4.Test period: can be set freely, minimum 10s

5.Test aerosol: DEHS

6.Counter: Six Channels 0.3 0.5 1 3 5 10μm

7.Accuracy of flow meter: 2.5%

8.Accuracy of pressure gauge: 1%

9.Dimensions( L*W*H) : 750×800×1750mm.

Environment requirements

1. Temperature: 25 ° C ± 5 ° C;

2. Relative humidity: 55% RH ± 15%;

3. Power supply: AC220V, 50Hz; power consumption is about 1000w.