Test Overview

It is used to evaluate the performance of air intake filters . Below are the key test parameters:

1. Restriction and Differential Pressure Test

· Test Purpose: Measures resistance variations at different airflow rates to plot the resistance-airflow curve.

· Test Method:

o Select five flow rate points between 50% and 150% of the rated flow.

o Record the pressure drop (ΔP) at different flow rates.

· Application: Evaluates airflow capacity and ensures the filter does not excessively restrict engine intake.

2. Initial Efficiency

· Test Purpose: Determines the filter’s efficiency in capturing particles at the start of operation.

· Test Method:

o Uses A4 Fine (fine dust) or A2 Coarse (coarse dust) for testing.

o Adds either 20g of dust or a mass equivalent to six times the flow rate (m³/min) (whichever is greater).

o Weighs the test filter and absolute filter increment, calculating initial efficiency (%).

· Application: Evaluates the initial filtration capability of new filters.

3. Full-Life Efficiency

· Test Purpose: Measures overall filtration efficiency when the filter reaches its final restriction.

· Test Method:

o Dust is continuously introduced until the filter reaches its final pressure drop (e .g., 250 mmH₂O or 2.5 kPa).

o Measures cumulative filtration efficiency over the entire test.

· Application: Provides insight into the filter’s performance over its lifespan.

4. Incremental Efficiency

· Test Purpose: Evaluates filtration efficiency at different loading stages before reaching the final restriction.

· Test Method:

o Efficiency is measured at 10%, 25%, and 50% of the difference between final and initial pressure drop.

o Weighs the test filter and absolute filter, calculating efficiency at each stage.

· Application: Assesses how filtration efficiency changes over time.

5. Dust Holding Capacity Test

· Test Purpose: Measures the total dust mass retained in the filter when it reaches its final restriction.

· Test Method:

o Records the total weight difference of the filter before and after the test to determine its dust holding capacity.

o The test stops when the rated final restriction (e.g., 2.5 kPa) is reached.

· Application: Determines filter longevity and replacement intervals.

Special Advantages

1. Multi-Function Testing Capability

· The equipment supports not only dust holding capacity testing but also initial resistance testing, resistance-airflow curve analysis, and more, meeting various testing requirements .

· Fully automated testing process, reducing manual intervention and improving efficiency and accuracy.

2. Intelligent Testing Process

· Guided testing system, automatically prompting each step to reduce operational difficulty.

· Automatic electronic scale data reading, precise calculations with no need for manual recording or calculations .

· Automatic airflow and pressure detection, starting the test automatically when conditions are met, ensuring reliable data .

3. High-Precision Nozzle Flow Meter

· Automatic nozzle switching, ensuring accurate flow rate measurement for different testing needs.

· One-touch operation, allowing easy selection of standards and test parameters.

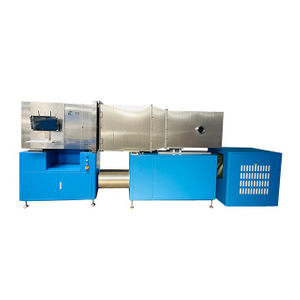

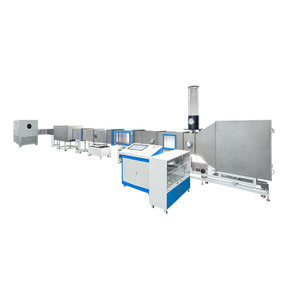

4. High Adaptability and Easy Installation

· Compact design, small footprint, suitable for laboratories and industrial applications.

· Easy installation and flexible design, customizable testing solutions.

· Compatible with various shapes and sizes of filters, making testing straightforward.

5. High-Performance Filtration System

· Uses F8 V-bank reinforced absolute filters, ensuring stable operation under specific pressures and providing more accurate test results.

Software and Results

1. Real-Time Monitoring and Data Visualization

· Real-time monitoring of resistance and airflow changes, providing intuitive data feedback.

· Visual data presentation, displaying test curves clearly for easier analysis.

· Multiple alerts and warning functions, reducing human error and simplifying operation.

2. Results Output and Data Management

· Automatically generates complete test reports and print labels in Excel format, allowing users to edit and adjust as needed, with clear data analysis and conclusions.

· Supports customization of special formats and multilingual templates, catering to different customer needs.

· Regular automatic backup of historical data, preventing data loss.

3. Remote Monitoring and Maintenance

· Integrated camera and remote control system, enabling remote operations:

o Remote fault diagnosis

o Remote debugging

Technical Data

Items | Parameter |

Air flow rate | 500~4800m3/h, customized |

Pressure drop | 0~10000 Pa |

Testable filter size | Filter assembly testing is not restricted, filter element testing requires a adapters |

Dust feeder | SC-189, A2/A4 |

Dimension (with FFU) | 6500mm×3500mm×1800mm |