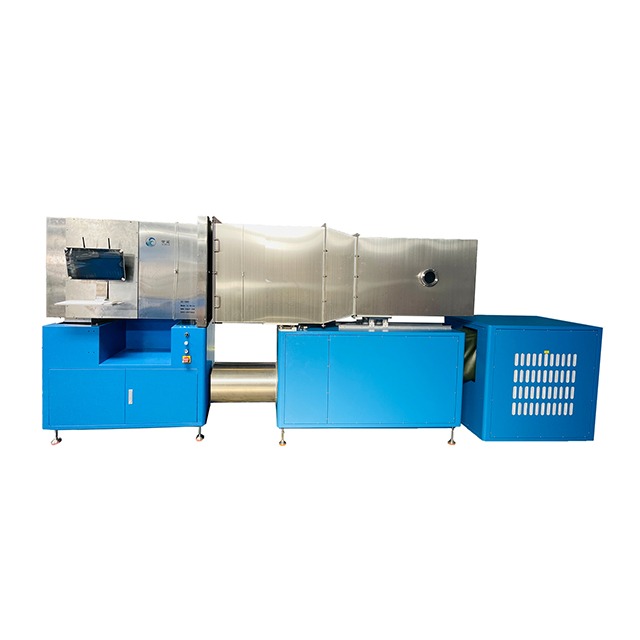

General Ventilation Air Filter Test System SC-16890

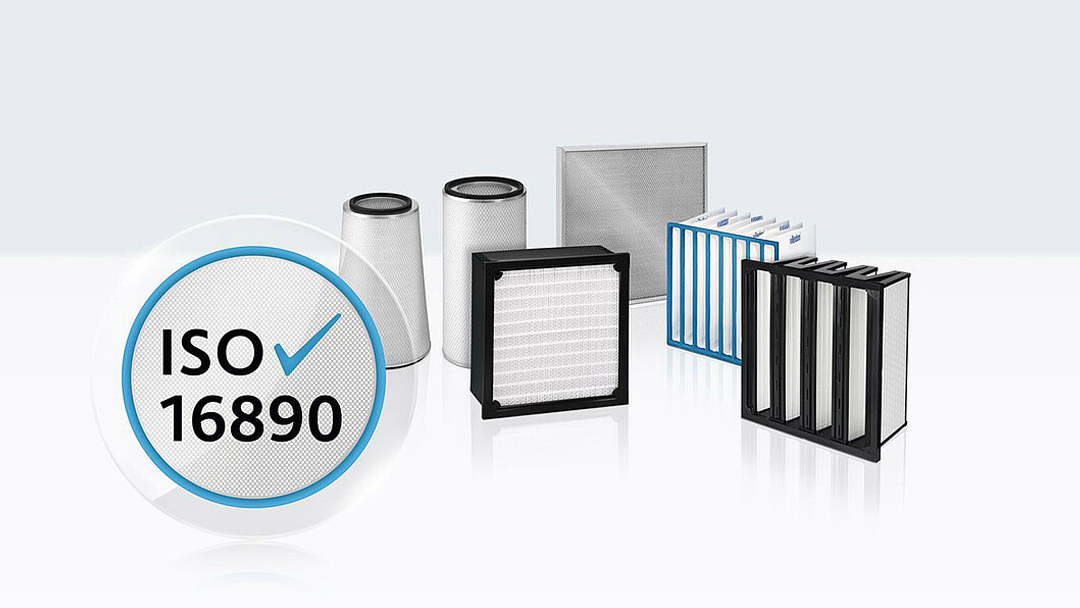

Fully compliant with ISO 16890 — providing accurate, reliable, and traceable testing solutions for HVAC filters in real-world conditions.

Why ISO 16890 Matters

Global Standard – Replaces EN779 with a harmonized, realistic method.

Particle-Based Testing – Evaluates filters against PM1, PM2.5, and PM10.

Real-World Accuracy – Includes electrostatic neutralization (IPA treatment) to reflect long-term performance.

Advantages of Air Filter Test System

SCPUR-Building Reliable Systems in a Specialized Field.

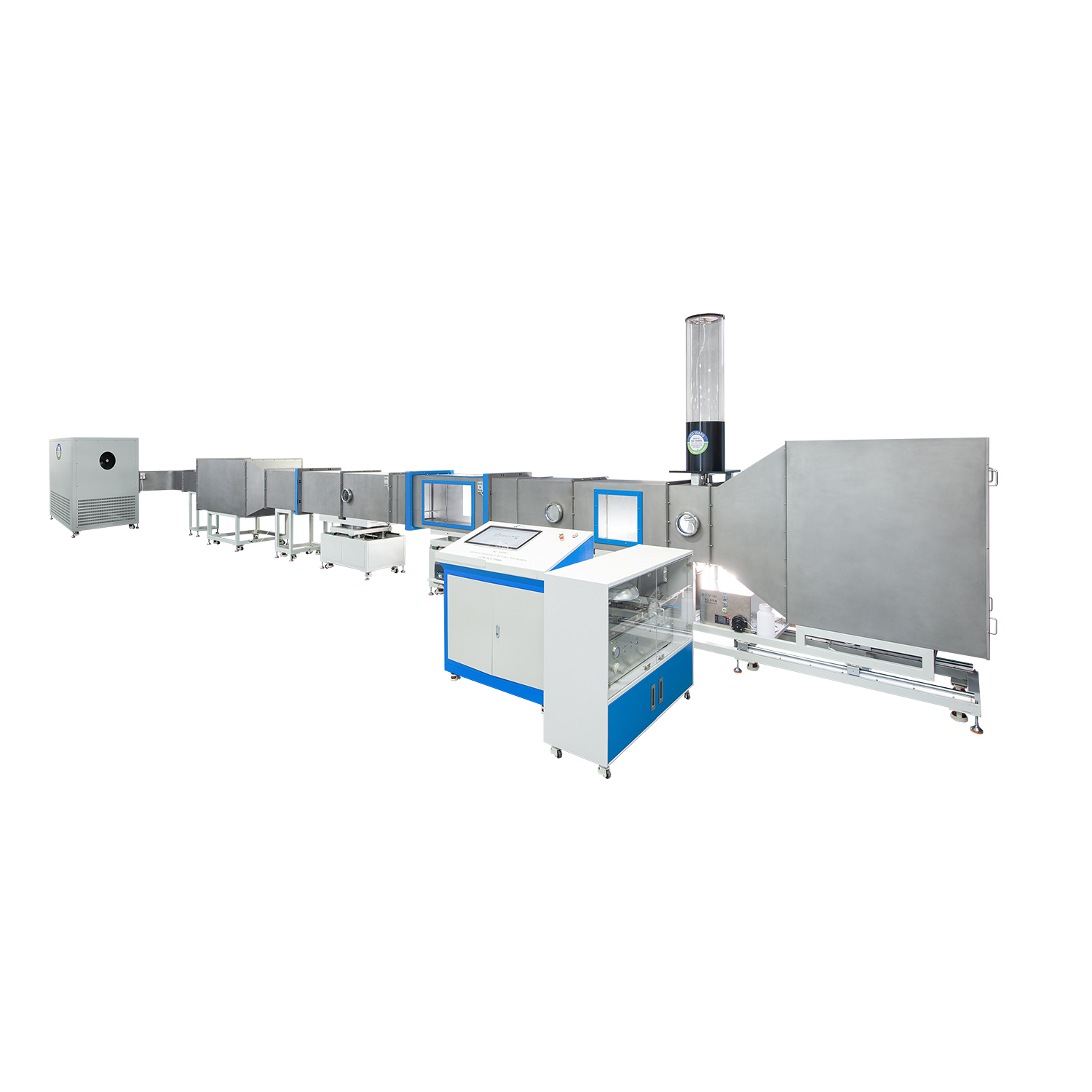

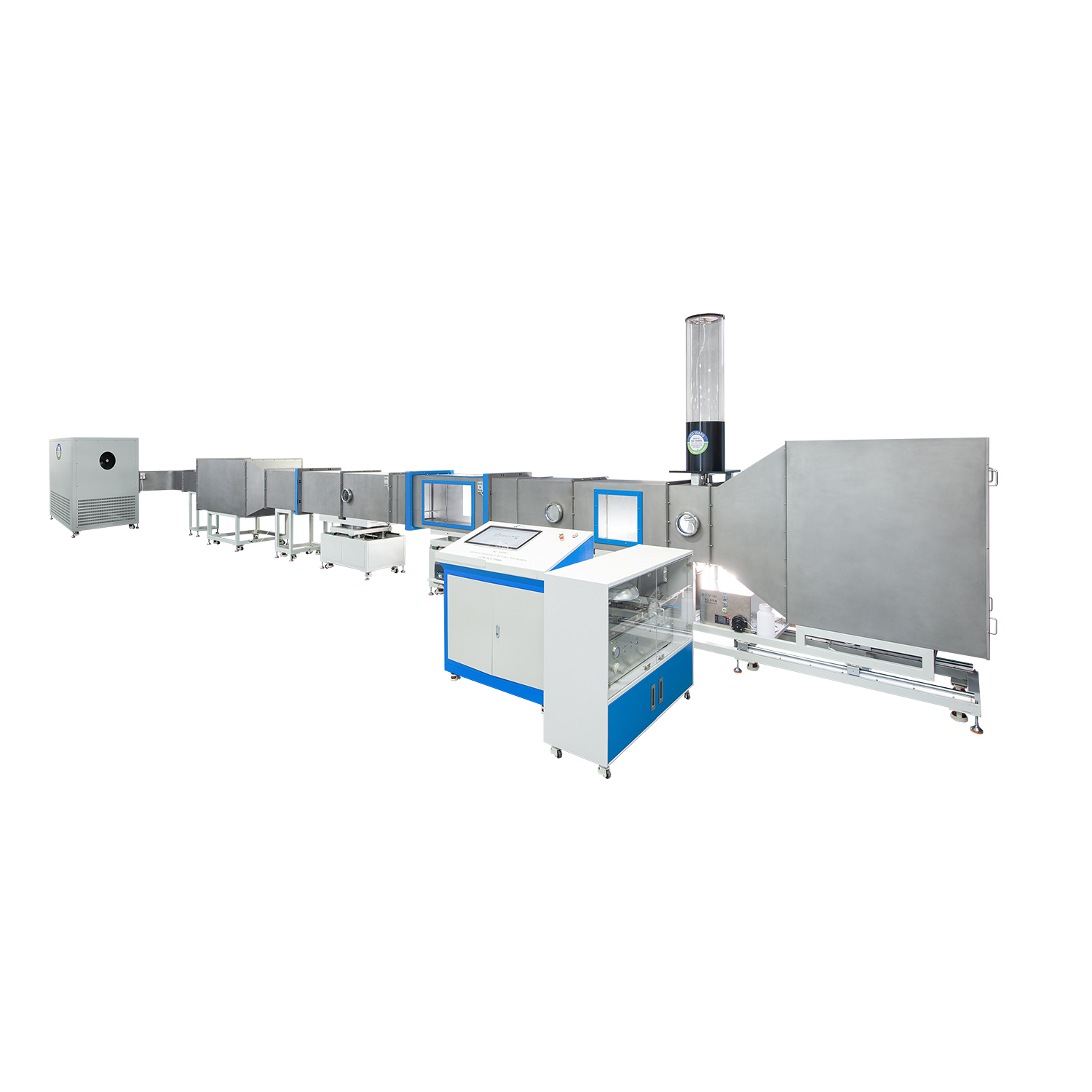

All ISO 16890 tests, one system

Run particle removal, airflow vs. pressure, and dust-loading in a single pass—then auto-generate ePM1/ePM2.5/ePM10 ratings with clear reports and labels. Fit for R&D, incoming inspection, and batch QC.

Automated, traceable, reliable

One-click sequences with stable airflow, automatic upstream/downstream sampling, and a built-in discharge step deliver repeatable results. Every run is logged and audit-ready to streamline customer and compliance reviews.

Data that lowers total cost

Use performance and loading curves to plan energy use and filter changeouts, support tenders with hard data, and cut disputes and after-sales costs across the product lifecycle.

Applications

Application1

Application2

Application3

General Ventilation Air Filter Test System SC-16890 Benefits

Faster bid-ready compliance

Generate ISO 16890 ratings and audit-ready reports in-house, cutting third-party wait time and accelerating tenders and product launches.

Smarter design, fewer iterations

Get particle removal, pressure–flow, and dust-loading curves in one run to choose media and geometry with confidence—before costly prototyping.

Lower risk through traceability

Batch-level data, incoming inspection, and consistent test sequences reduce variability, prevent off-spec shipments, and resolve supplier/customer disputes.

Proof that helps you sell

Embed clear ePM ratings and performance curves in proposals and datasheets to justify value, speed buying decisions, and drive repeat orders.

Why choose SCPUR Tech

We focus on the specialized field of filtration testing and build stable, practical, upgradable, and reliable systems—so you can trust every data point and move faster from validation to decision.

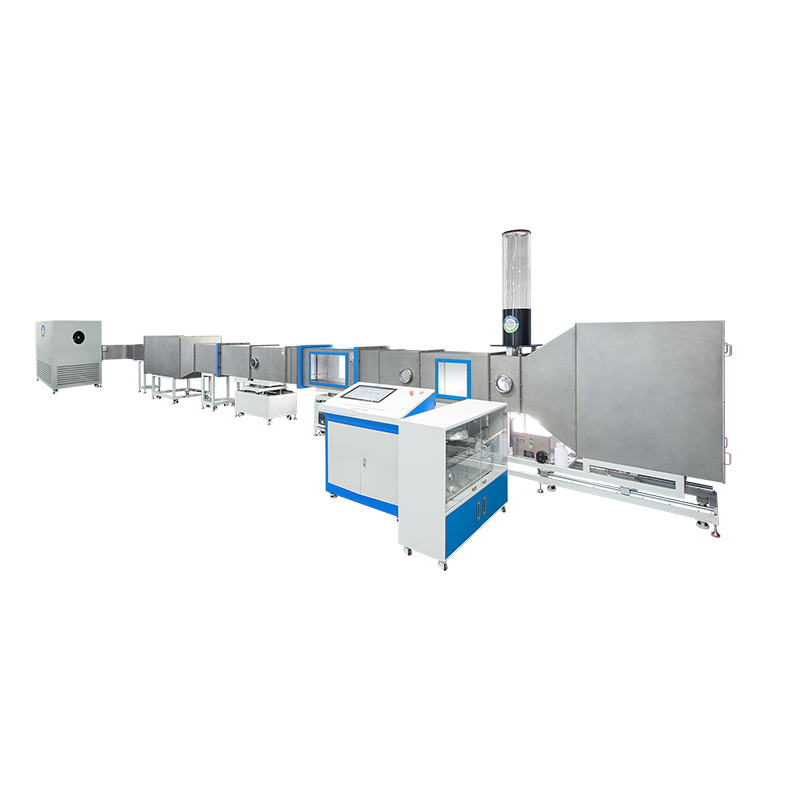

System-level engineering for repeatable results

We design testers as complete systems—optical sensing, aerosol control, process logic, sampling, software, and service—so your data is stable, comparable, and credible across labs and over time. This systems thinking is the core of our product philosophy.

Proven worldwide, independently developed

We build our own software, hardware, and core modules, and our equipment is used in 38+ countries by nearly 1,000 clients—including 100+ overseas customers—so you benefit from field-tested reliability, not prototypes.

Certified quality with lifecycle support

ISO 9001–certified quality management, CE certifications, remote diagnostics, alarms, data calibration, and responsive after-sales service—backed by a one-year warranty and lifetime maintenance—keep your lab running with confidence.

Modular, upgradable, and made to fit

A modular architecture means easier customization today and clean upgrade paths tomorrow; automated workflows, clear curves, and secure data backup reduce operator error and make results easier to act on.

Contact Us

Boasting a team of seasoned experts, while offering technical assistance and comprehensive one-stop solutions to the global marketplace.

Related Blogs

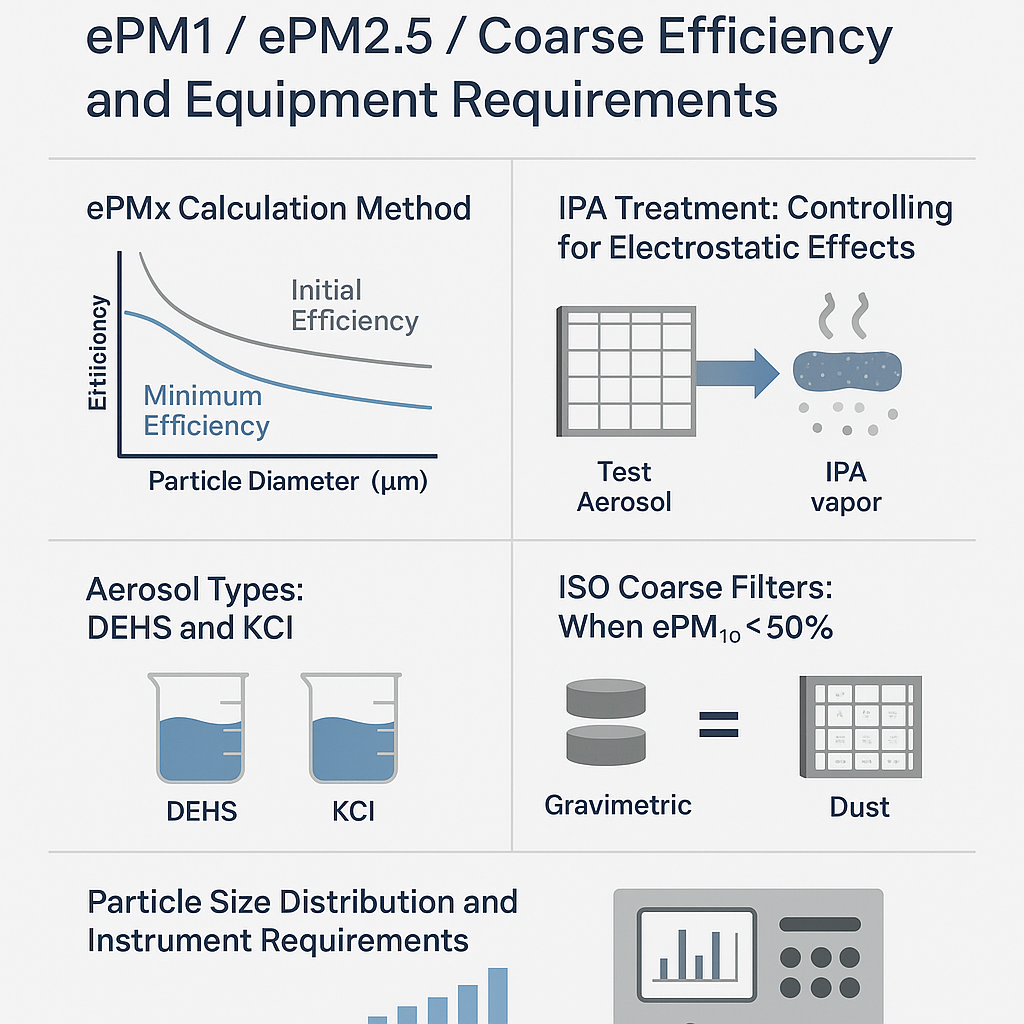

Understanding ISO 16890: Test Methods for ePM1 / ePM2.5 / Coarse Efficiency and Equipment Requirements

In modern air filtration applications, users are increasingly concerned with how well filters remove particles in the PM2.5 and PM10 size ranges. ISO 16890 is now the leading international standard for evaluating air filter performance for general ventilation. This article provides a clear explanation of how ISO 16890 defines and measures ePM1, ePM2.5, ePM10, and Coarse filtration efficiencies, as well as key topics such as aerosol types, particle size classification, data processing, and equipment design requirements.

Read MoreComparison of EN 1822, ISO 29463, and IEST-RP-CC003.4: Testing, Classification, Particle Size Considerations, and Application Scope

EN 1822, ISO 29463, and IEST-RP-CC003.4 are three key standards for classifying and testing HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters. While they share similarities, they differ significantly in testing methods, particle size considerations, classification, and application scope. Below is a comprehensive comparison.

Read MoreISO 16890: Understanding the Standard for Air Filtration

In today's world, with increasing concerns about air quality and its impact on health, the need for effective air filtration systems has become paramount. ISO 16890 stands out as a crucial standard in this regard, providing a framework for evaluating the performance of air filters. Let's delve into

Read MoreWhat are the differences between pre-filters, fine filters and HEPA filters?

Pre-filters, fine filters and HEPA filters are also filters. What are the differences?

Read More

Get Touch With Us

Contact Info

+86-17685580855

hongc@scpur.com