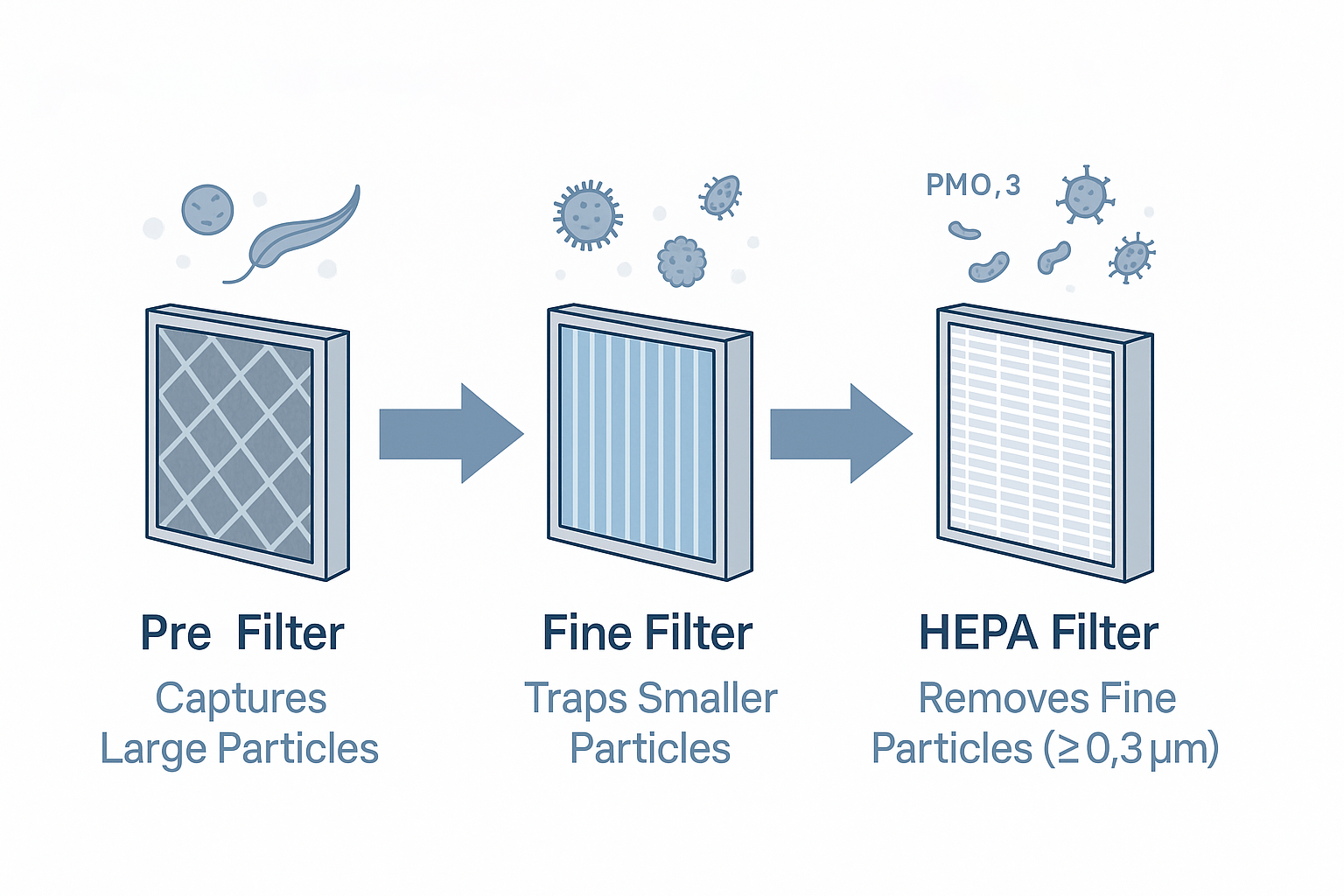

Understanding Pre Filter, Fine Filter & HEPA Filter -

Key to Effective Air Filtration

What are Pre Filter, Fine Filter and HEPA Filter?

Pre-filter, fine filter, and HEPA filter are commonly used in a multi-stage air filtration system. Pre-filters capture large particles like dust and hair, protecting the filters that follow. Fine filters remove medium-sized particles such as pollen and mold spores, improving air quality. HEPA filters trap extremely fine particles including bacteria and viruses, with an efficiency of 99.97% or higher. Together, these filters work in stages to enhance filtration efficiency and extend the system’s lifespan.

Application Scenarios: Where Are Filters Used?

Pre filter, Fine filter and HEPA filter are essential for clean air environments, from hospitals to semiconductor manufacturing.

Learn how different industries rely on high-efficiency filtration:

Medical & Cleanrooms

Industrial & Manufacturing

HVAC & Air Purification

Automotive & Aerospace

Testing Methods:

How to Ensure the Quality of Pre Filter, Fine Filter & HEPA Filter?

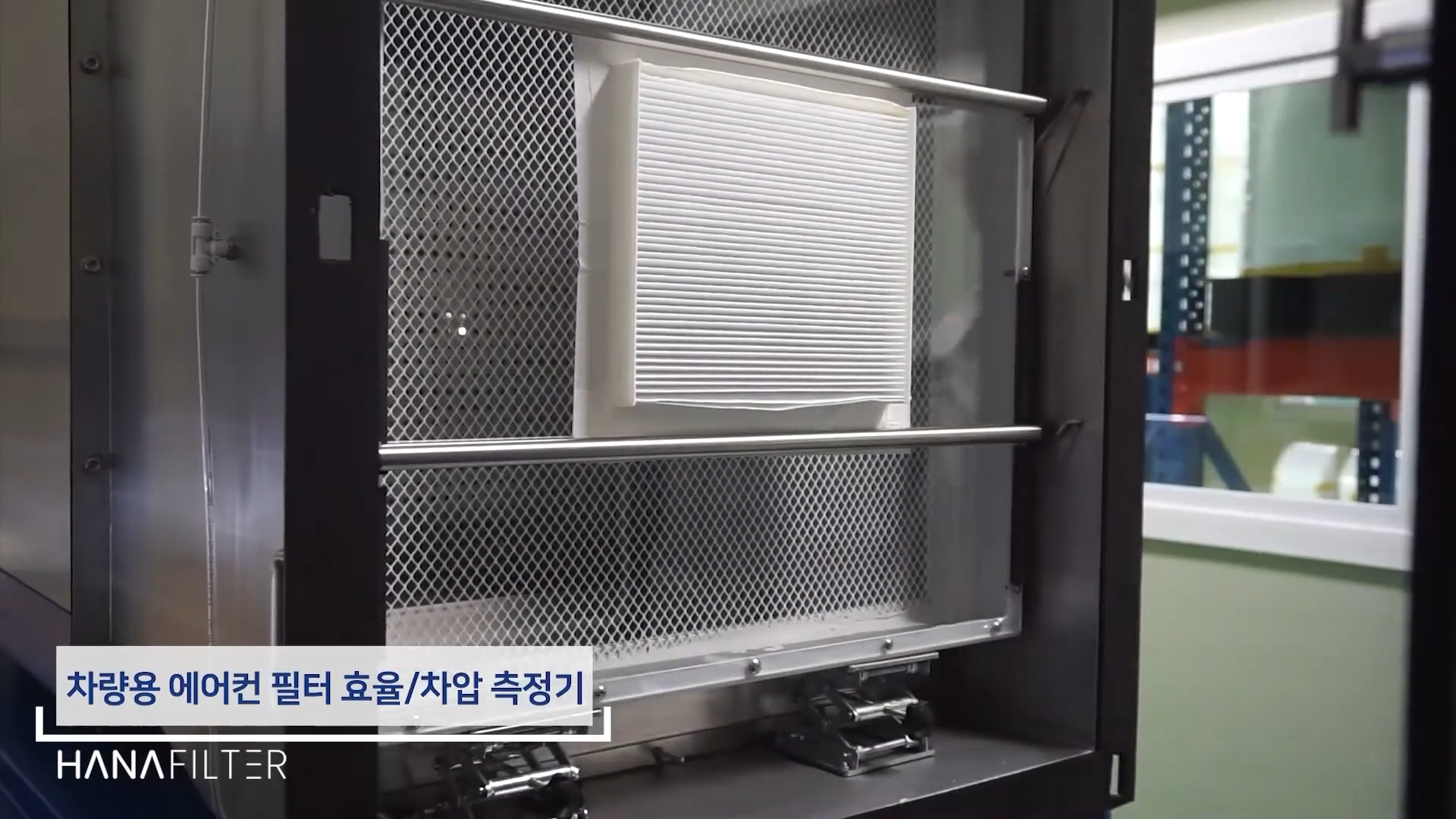

Ensuring the performance of Pre filter, Fine filter and HEPA filter requires advanced testing methods such as particle counting, airflow resistance measurement, and integrity testing. Proper evaluation guarantees high filtration efficiency.

Industry Standards:

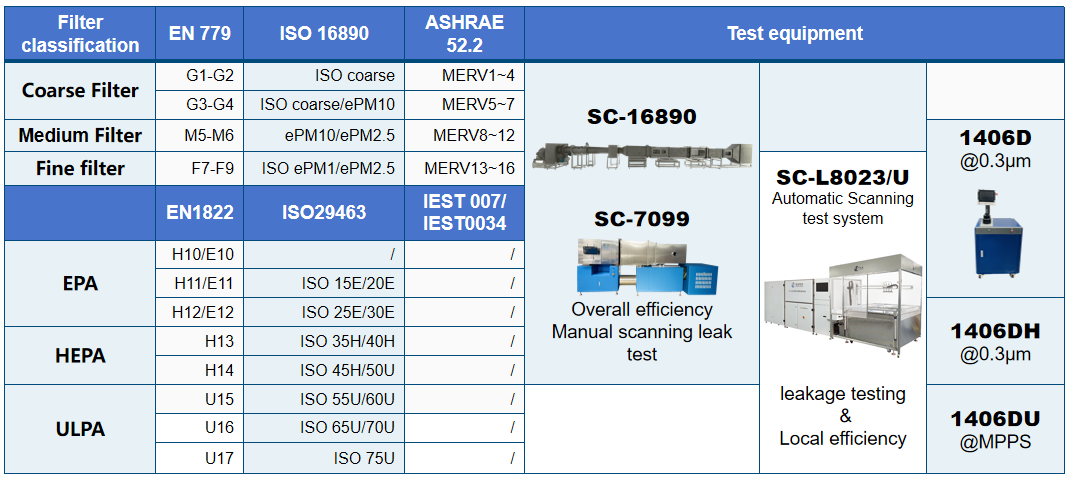

Regulatory Compliance for HEPA & Fine, Pre Filters

HEPA, fine, and pre filters are subject to different industry standards and regulations. HEPA filters are typically classified and individually tested according to EN 1822 or ISO 29463, with H13 and H14 grades commonly used in cleanrooms and pharmaceutical environments, often requiring compliance with FDA or GMP guidelines. Fine and pre filters are generally rated under ISO 16890 or ASHRAE 52.2 (MERV) standards—fine filters for capturing smaller particles (e.g., pollen, spores) and pre filters for larger particles (e.g., dust, fibers). These standards ensure compliance with indoor air quality (IAQ) requirements and building codes across various industries.

Testing Equipment:

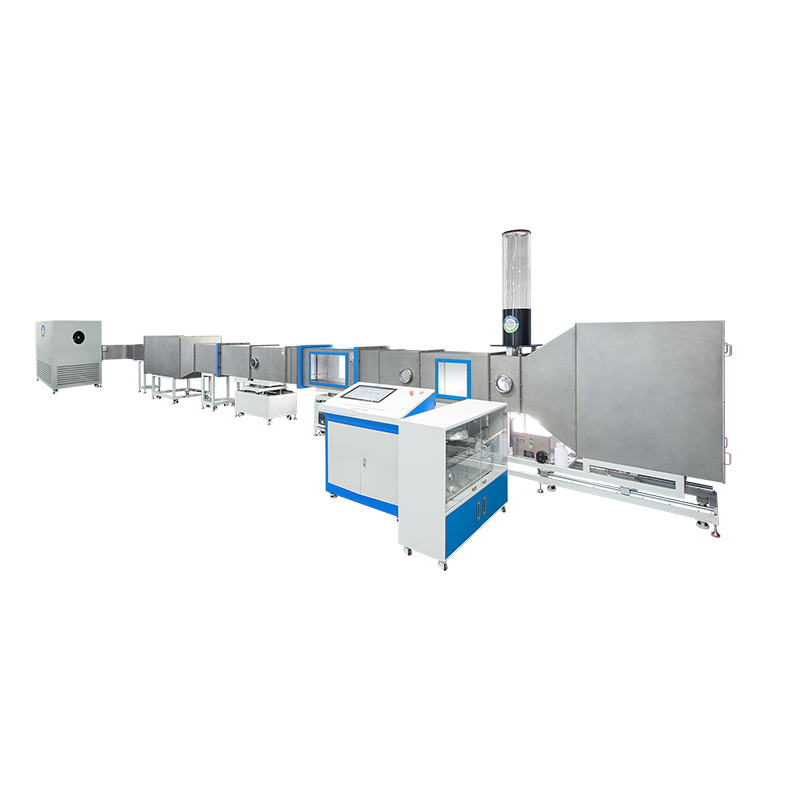

Advanced Solutions for Filter Performance Testing

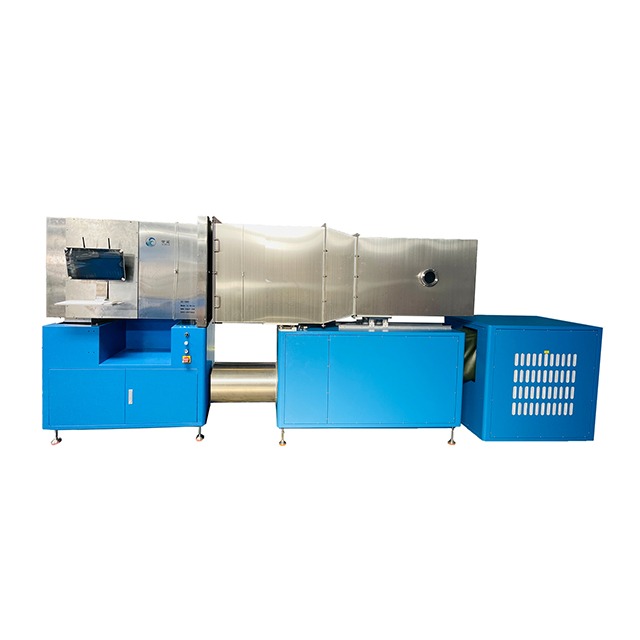

SCPUR Technology – A Trusted Chinese Manufacturer of Filter Testing Equipment

Why Testing Matters:

The Role of Filter Testing in Air Purification

Accurate testing of pre filters, fine filters, and HEPA filters is crucial to ensuring effective air purification. Even the highest-quality filters can underperform without proper verification. Rigorous testing validates filtration efficiency, airflow resistance, and structural integrity—safeguarding clean air environments and ensuring compliance with industry standards.

Case Studies:

Proven Performance of Filters with Certified Testing

Leading pharmaceutical companies rely on certified HEPA filter testing to maintain sterile environments. See how our solutions contribute to their success.

Frequently Asked Questions (FAQs)

Q1: What is the difference between Pre Fine and HEPA filters?

A: Pre Fine filters are designed for capturing larger dust particles, extending the lifespan of HEPA filters, which remove up to 99.97% of airborne particles as small as 0.3 μm.

Q2: How often should HEPA filters be replaced?

A: The lifespan of a HEPA filter depends on usage and environmental conditions. In general, HEPA filters in HVAC systems should be replaced every 6 to 12 months, while industrial and medical-grade filters may require more frequent changes.

Q3: How do I test the efficiency of my HEPA filter?

A: HEPA filters are tested using particle counting methods, airflow resistance tests, and integrity tests. Using certified filter testing equipment ensures accurate performance evaluation.

Q4: What standards should HEPA filters comply with?

A: HEPA filters should meet EN 1822, ISO 29463 to ensure high efficiency and safety in air filtration applications.

Q5: Can HEPA filters be washed and reused?

A: Most HEPA filters are not designed for washing. Washing can damage the filter media and reduce filtration efficiency. Some industrial-grade HEPA filters have reusable components, but professional testing is recommended after any cleaning process.

Q6: Why is HEPA filter testing important?

A: Without proper testing, HEPA filters may fail to perform effectively, leading to reduced air quality and potential contamination in controlled environments.

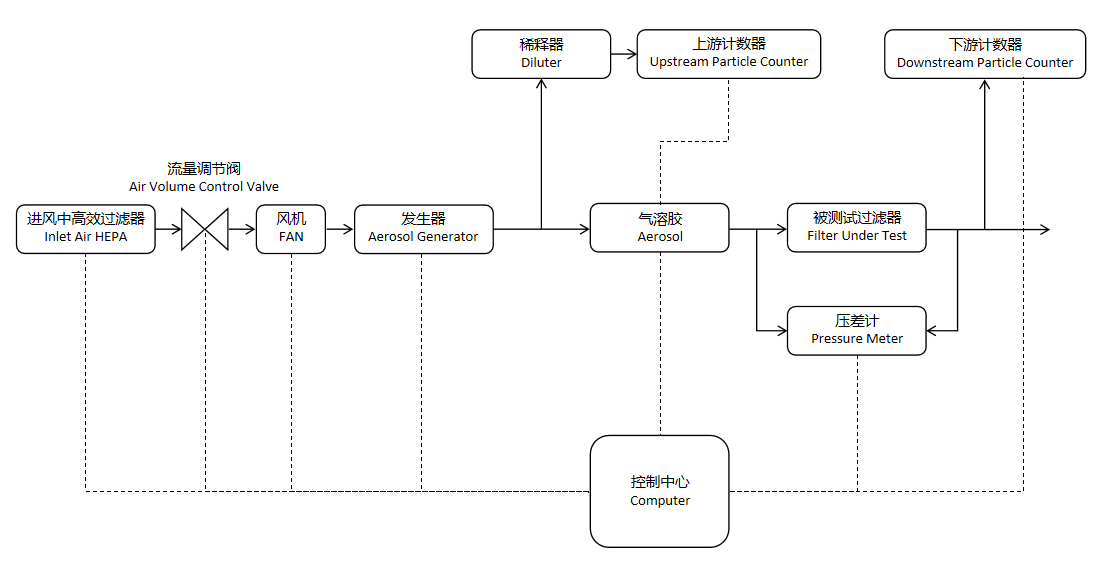

Q7: How does filter testing equipment work?

A: Filter testing machines evaluate HEPA and Pre Fine filters using advanced methods like particle counting, pressure drop measurement, and leakage detection, ensuring compliance with industry standards.

Insights on Air Filtration & Testing Technologies

-

ISO 29463 originates from EN1822, which defines EPA, HEPA and ULPA filters commonly used in industry. While ISO 29463 maintains the classification of EPA, HEPA and ULPA.But replace E10-E12, H13-H14 and U15-U17 with the following 13 filter levels. The ISO 29463 can't replace EN 1822, EN 1822 will continue to be valid.Expert Ideas

ISO 29463 originates from EN1822, which defines EPA, HEPA and ULPA filters commonly used in industry. While ISO 29463 maintains the classification of EPA, HEPA and ULPA.But replace E10-E12, H13-H14 and U15-U17 with the following 13 filter levels. The ISO 29463 can't replace EN 1822, EN 1822 will continue to be valid.Expert Ideas

Contact Us:

Learn More About

Filter Testing Solutions

Need to ensure your Pre filter, Fine filter and HEPA filter meet the highest standards? Contact us today for a customized testing solution!