Bottlenecks in Industrial Detection Efficiency and Limitations of Traditional Testing

Pain Points of Industry Efficiency

In the industrial production of filter products, low detection efficiency has become a significant obstacle that affects production capacity and increases costs. For filter manufacturers, a time - consuming detection process often leads to extended production cycles. For example, if a traditional detection method takes several hours to test a single batch of filters, it directly restricts the daily output, making it difficult for enterprises to meet market demands in a timely manner. Moreover, the high - cost labor required for manual operation and monitoring during the long - term detection process further inflates production costs, reducing the competitiveness of enterprises in the market.

Drawbacks of Traditional Testing Methods

Traditional filter product testing methods, such as the overall blocking - type testing, have obvious deficiencies in terms of efficiency. This type of testing usually requires frequent disassembly and assembly of products. Each time a new batch of filters is tested, workers need to spend a lot of time installing the product on the testing equipment and then removing it after the test, which not only consumes a lot of labor but also increases the risk of product damage during the handling process. In addition, traditional testing equipment often requires a long time for debugging and calibration before each test, including adjusting parameters such as pressure, flow rate, and temperature, which greatly extends the overall testing time.

Introduction of the Solution

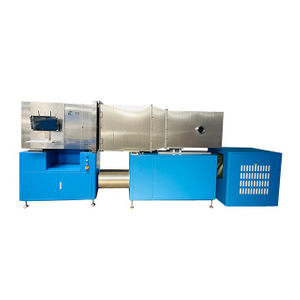

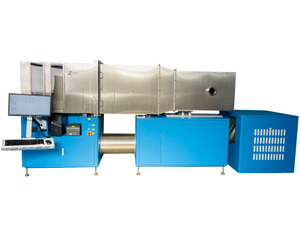

To address these efficiency - related challenges, Scince Purge Technology (Qingdao) Co., Ltd.'s Filter Tester adopts the bypass testing principle. This innovative technology provides a new approach to break through the bottleneck of traditional detection efficiency, aiming to revolutionize the filter product testing process by optimizing the testing workflow and reducing unnecessary time consumption.

In - depth Analysis of the Core Principles of Bypass Testing

Overview of the Principle

The bypass testing principle of the Filter Tester is based on the establishment of a main path and a bypass system. During the testing process, products can continue to flow through the main path, maintaining the continuity of the production line. At the same time, a certain number of products are diverted to the bypass for detection. This design allows for the inspection of filter products without interrupting the production process, achieving the goal of "testing while producing" and greatly improving overall production and testing efficiency.

System Composition

The bypass testing system of the Filter Tester consists of several key components. The main path serves as the product conveying channel, ensuring the smooth flow of filter products during normal production. The bypass is equipped with a complete set of detection units, including sensors, testing probes, and data - processing devices, which are responsible for accurately detecting the performance of filter products. The switching device between the main path and the bypass is precisely controlled, and it can quickly and accurately divert products to the bypass for testing according to the set rules. The control logic, mainly realized by the Programmable Logic Controller (PLC), coordinates the operation of each component, ensuring the seamless operation of the entire system.

Technical Advantages

Compared with traditional testing methods, the bypass testing principle simplifies the testing process in essence. It eliminates non - essential links such as product loading and unloading and long - time equipment adjustment before each test. In traditional testing, these preparatory steps may account for 30% - 50% of the total testing time. In contrast, the bypass testing system can directly start the detection once the product enters the bypass, reducing the time wasted on unnecessary operations and significantly improving the efficiency of the detection process.

Paths to Improve Detection Efficiency of Filter Tester through Bypass Testing

Realization of Continuous Detection

The bypass testing principle enables continuous detection of filter products. Unlike traditional testing methods that require starting and stopping for each individual test, in the bypass testing system, products can be continuously diverted to the bypass for inspection while new products are constantly fed into the main path. For example, in a production line that produces 1000 filters per day, the continuous detection mode of the Filter Tester can increase the daily testing volume by 2 - 3 times compared with the traditional intermittent testing method, ensuring that all products can be inspected in a timely manner without causing backlogs in the production process.

Reduction of Preparation Time

The bypass testing principle significantly reduces the preparation time required for detection. Since the main path always maintains the normal production state, there is no need to re - adjust equipment parameters or calibrate instruments for each test. The system can automatically adapt to different product specifications and testing requirements through pre - set programs in the PLC. For instance, when switching between different models of filters, the Filter Tester can complete the adjustment of the testing parameters within a few minutes, while traditional equipment may take half an hour or more for the same task.

Multi - task Parallel Mechanism

In the bypass testing mode, the Filter Tester can achieve the parallel operation of detection and production tasks. While the bypass is conducting product detection, the main path continues to produce products, which greatly improves the utilization rate of equipment. This parallel mechanism not only increases the output of products but also ensures the quality of products through timely detection. Enterprises can make full use of production time, reduce idle time of equipment, and achieve more efficient production management.

Synergistic Effects of Bypass Testing and Other Technologies

Integration with Intelligent Control

The bypass testing principle works in harmony with the intelligent element control system of the Filter Tester, such as the PLC and Human - Machine Interface (HMI). The PLC can precisely control the switching of the bypass and main path, as well as adjust the detection parameters according to real - time data feedback. The HMI provides operators with an intuitive interface, allowing them to easily monitor the operation status of the bypass testing system and make necessary adjustments. Together, they optimize the bypass detection process, realizing automated control and precise regulation, which further improves the efficiency and accuracy of the detection.

Support of Complementary Functions

Other product features of the Filter Tester, such as the quickly replaceable test templates and the automatic report - generation function, also play an auxiliary role in enhancing the efficiency of bypass testing. The quickly replaceable test templates can adapt to different filter product specifications in a short time, ensuring that the bypass testing system can handle a variety of products without significant interruptions. The automatic report - generation function can immediately generate test reports after each detection, saving the time for manual data collation and analysis. These functions form a joint force, comprehensively promoting the improvement of detection efficiency.

Application Value and Prospects of the Bypass Testing Principle

Summary of Practical Benefits

From the perspective of enterprise production, the bypass testing principle brings tangible benefits. It effectively reduces production costs by shortening the testing time and reducing labor input. The improvement in production capacity allows enterprises to meet market demands more quickly, accelerating the delivery cycle and enhancing customer satisfaction. In addition, the timely detection provided by the bypass testing system helps enterprises identify product quality problems in a timely manner, reducing the occurrence of defective products and further saving costs.

Potential for Industry Application

The bypass testing principle has broad prospects for application in the testing of filter products in various industries, such as automotive, electronics, and environmental protection. In the automotive industry, it can be used to test engine air filters and fuel filters more efficiently; in the electronics industry, it is suitable for testing air filters in clean rooms; in the environmental protection field, it can improve the testing efficiency of industrial exhaust gas filters. Its application has the potential to drive a transformation in the industry's detection mode, promoting the overall development of the filter product manufacturing industry.

Technical Development Direction

Looking ahead, the bypass testing technology of the Filter Tester is expected to develop towards greater intelligence and integration. In the future, it may be further integrated with emerging technologies such as artificial intelligence and the Internet of Things, realizing more intelligent decision - making and remote monitoring. This development trend will not only continue to improve the efficiency of filter product detection but also lead the technological upgrading of the entire industrial detection field, bringing new opportunities and challenges to the industry.

Conclusion

In an era where the industrial detection field constantly pursues high efficiency and precision, the bypass testing principle of the Filter Tester represents a technological innovation of profound significance. It has successfully shattered the efficiency constraints of traditional detection methods. By ingeniously establishing a coordinated operation model of the main path and bypass, it has made continuous detection, rapid switching, and multi - task parallelism a reality. The deep integration with intelligent control technologies, along with the collaborative efforts of complementary functions, not only enhances the detection efficiency but also ensures the accuracy and reliability of detection results.

If you are troubled by low - efficiency filter product detection and high costs, or if you aspire to stand out in industry competition with advanced detection technologies, the Filter Tester by Scince Purge Technology (Qingdao) Co., Ltd. is the ideal choice for you. We sincerely invite you to visit our official website at www.scpur.com to gain an in - depth understanding of the detailed technical parameters and successful application cases of the Filter Tester. You can also contact our professional team by leaving your information on the website to obtain personalized detection solutions. Embark on a journey of efficient and precise detection by learning more about the Filter Tester today!