Features

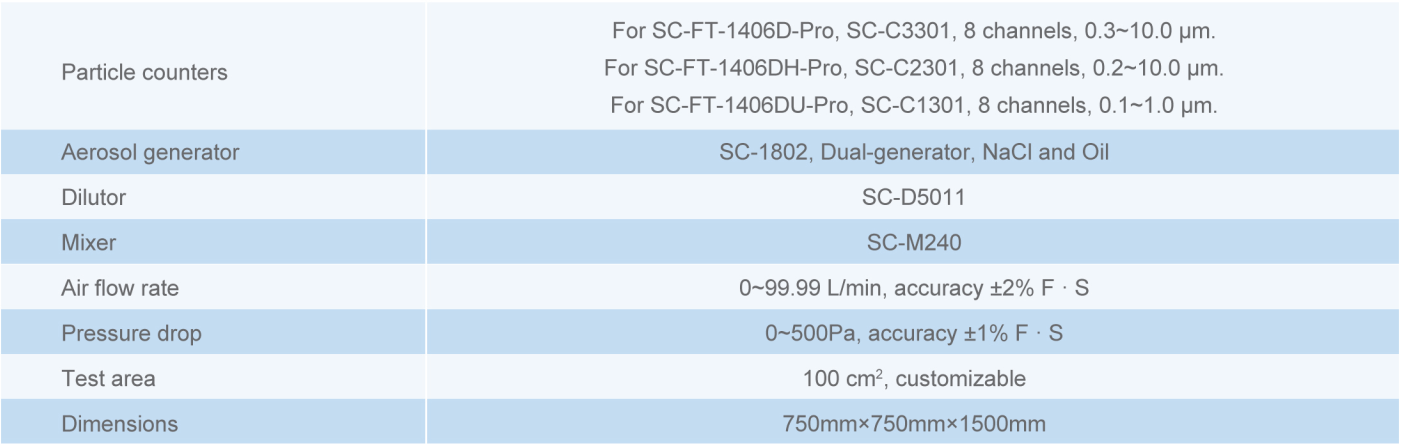

Particle counters as detectors

Remote trouble shooting and calibration are realised.

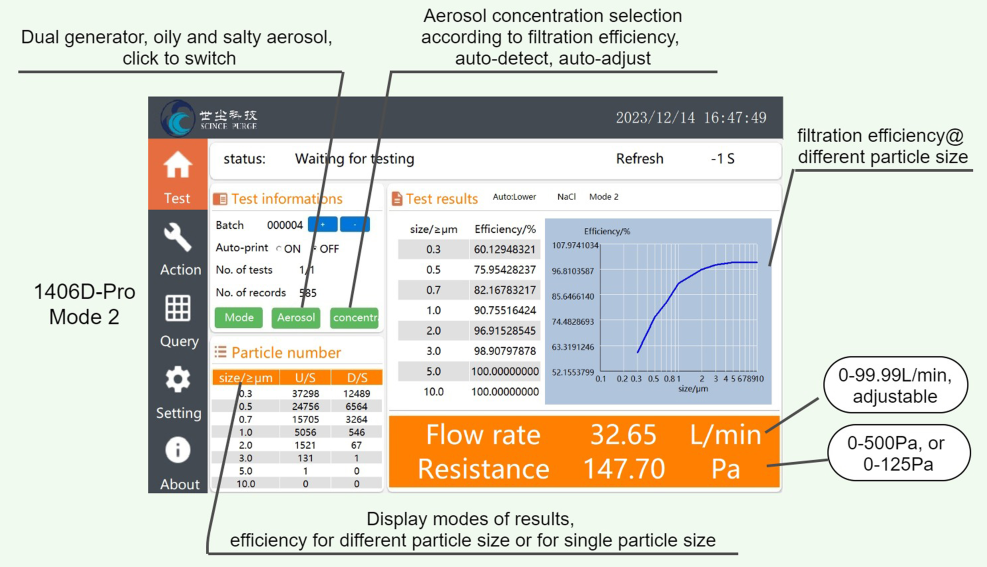

Highly automated. No need to manually adjust the test concentration.

switch the test aerosol.

Strong data storage and processing capability.

According to

NIOSH 42 CFR Part 84, EN 149,ASTM F2100-3.1.4, EN 14683:2005 etc.

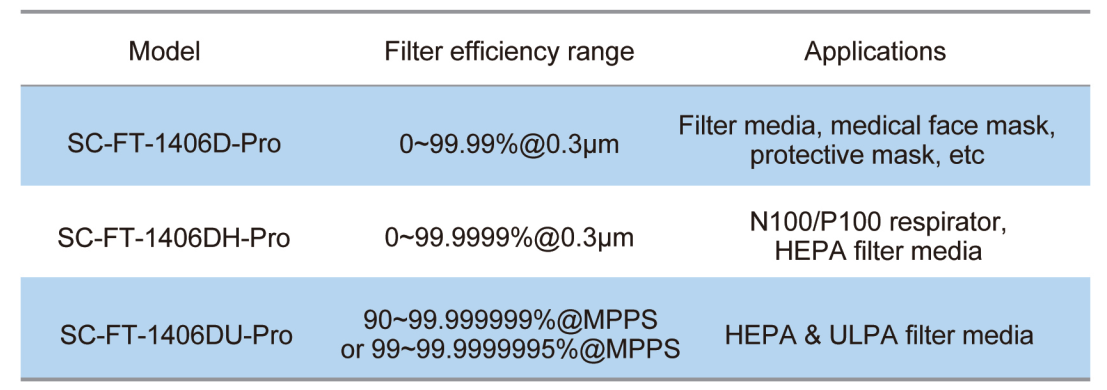

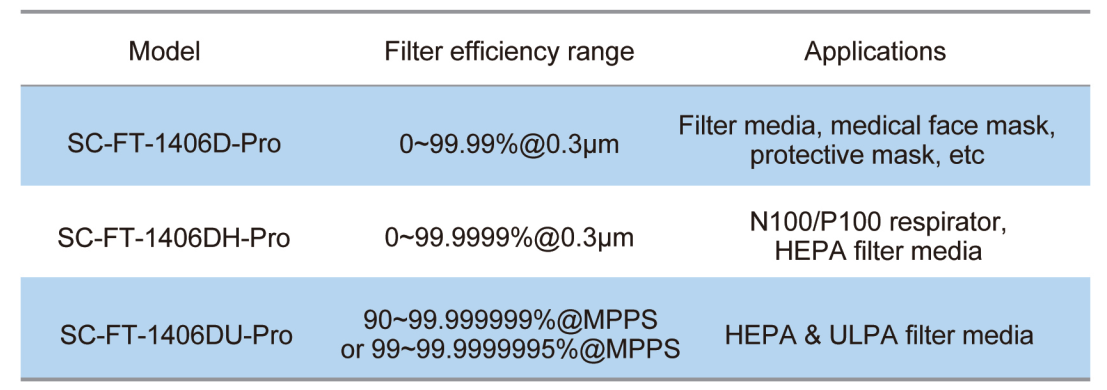

Applications

Filtration eficiency and resistance test for filter media, mask (respirator) and small filter element.

Quality control and materials inspection for filter media, mask and filter manufacturers.

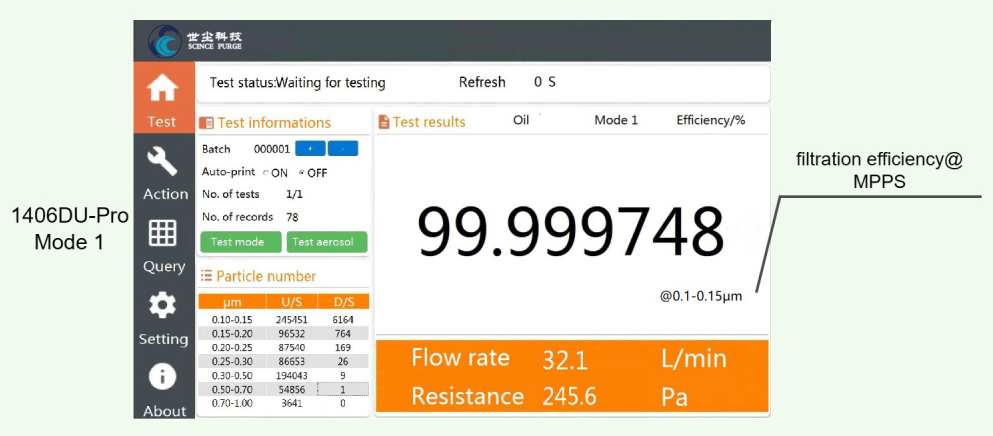

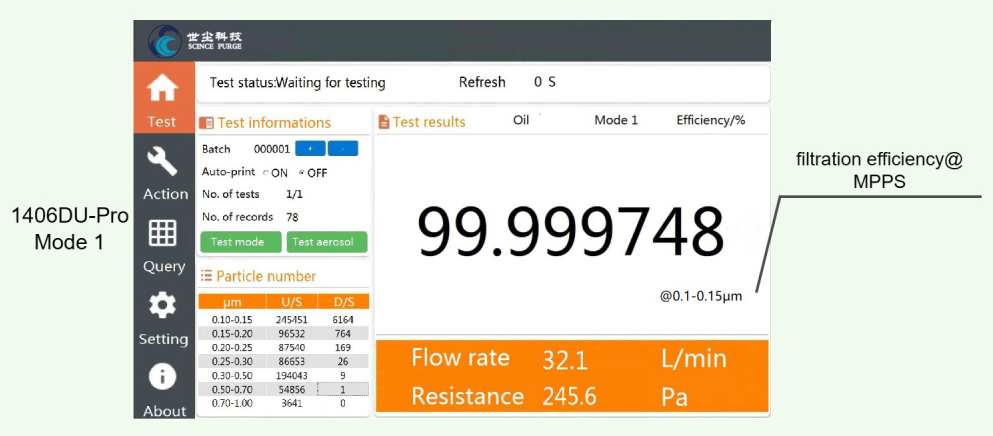

Interface and software

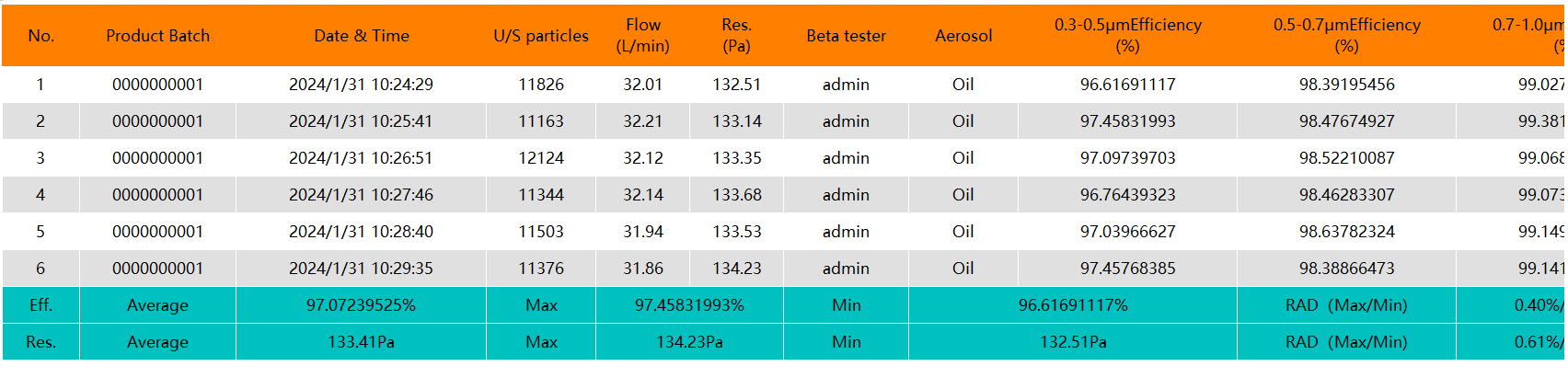

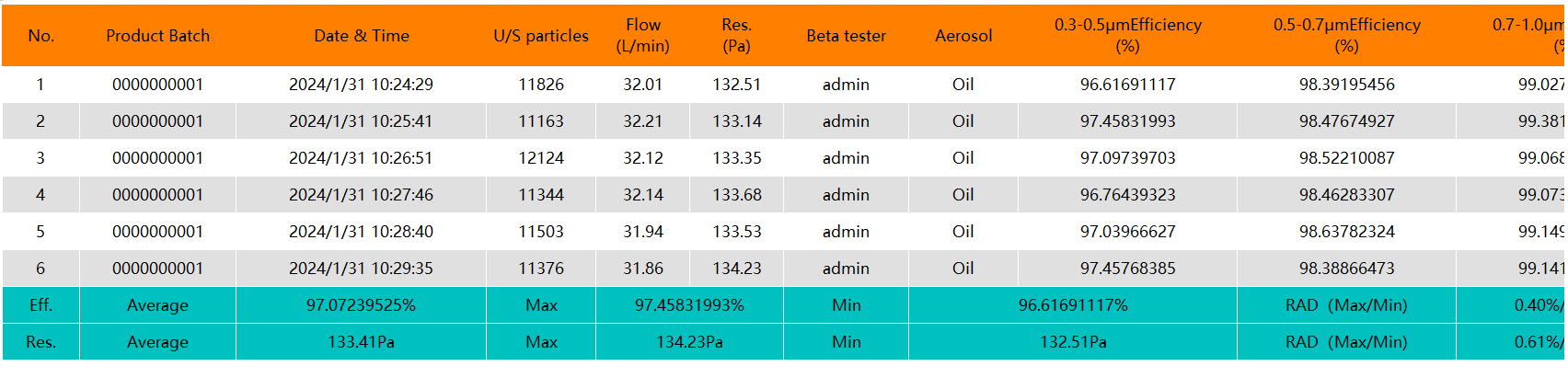

Data analysis

Users can select batches from the database and the system will automatically generate test results for theaverage,maximum, minimum, and deviation.

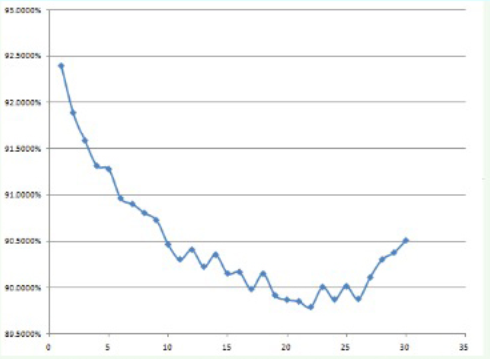

Load test for mask(1406D-Pro+)

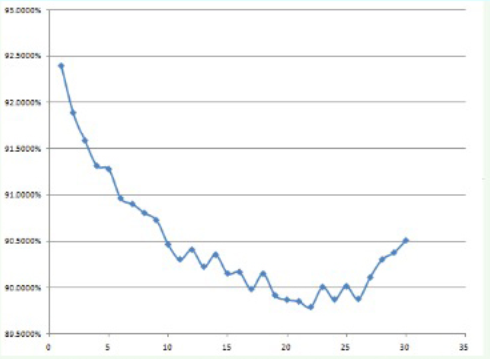

Modify the test cycle--Turn on high concentrationgenerator--Start test--Stop test after load quantityor time is qualified--Draw a curve according totest results

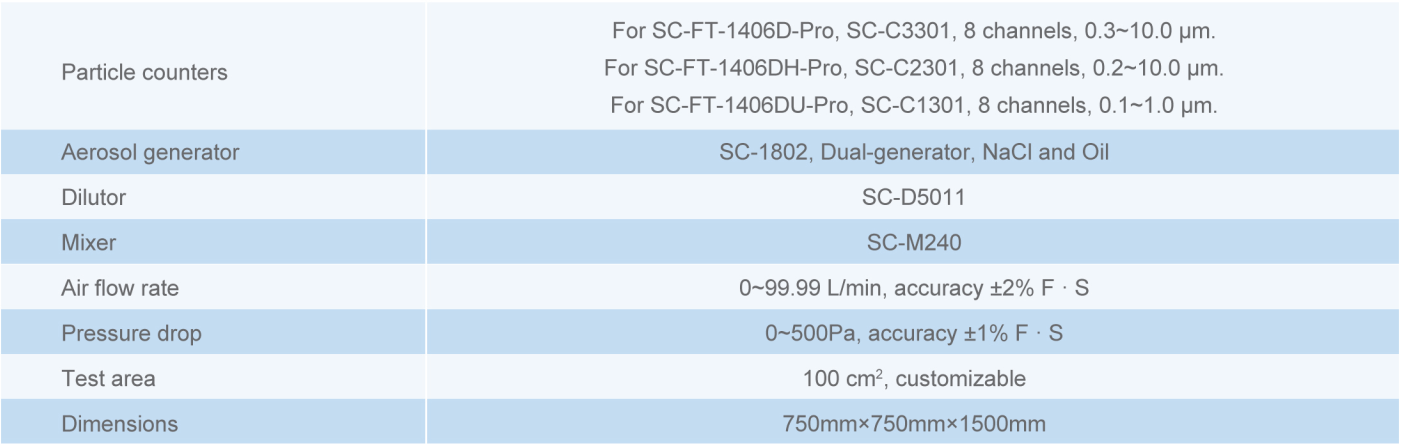

Technical parameters

Environment requirements

Temperature: (23±5)°C

Power supply: 220 V AC, 50Hz or 60Hz, 1000W

Air compression: >0.5 MPa 160L/min

Clean air source system(optional)

Air compressor: air storage capacity 160L,

pressure 0.7MPa,

exhaust volume 520L / min,

Voltage 380V or 220V,

power 6kw

High precision filter: treatment capacity≥ 1m3 / min,

pressure≤ 0.8MPa

Freeze dryer: treatment capacity≥ 1 m3 / min,

pressure≤ 1 MPa,

voltage 220 v

Pressure reducing valve: pressure ≤ 1MPa,

pressure regulating range 0.5-0.9mpa