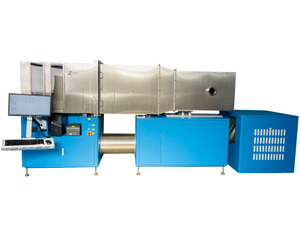

Significant advantages

The filter to be tested can be conveniently installed in the test fixture. Test aerosol and clean air are evenly mixed and passed through the tested filter. Resistance and filter efficiency are obtained by detecting the pressure difference and concentration difference downstream and upstream of the filter. Filters are graded according to their average efficiency.

Adopt the upper computer software system and the control main-board to form the electrical control cabinet, which ensures the stability of the control system.

The start and stop of the aerosol generator, the conversion of the upstream and downstream laser particle counter, and inflation and sealing all are automatically controlled by the corresponding solenoid valves.

The test system works under negative pressure, the air volume is set by software, and the frequency converter is used to realize the automatic control of the air volume.

Technical parameters

1. Output air volume: 500 ~ 3500m3/h.

2. Air volume error: ≤ 5% (variable frequency control is adjustable).

3. Maximum size of testable filter: 610mm×610mm×120mm. The minimum size is limited by the minimum test flow.

4. Aerosol: DEHS or KCl.

5. Sampling flow: 2.83l/min, ±5%.

6. Measurable resistance range: 0~500Pa.

Working conditions

1. Voltage: AC 380V,50Hz (three-phase five-wire system).

2. Power: 2500W.

3. Temperature: ( 23 ± 5) ° C.

4. Relative humidity: (20~70)%RH.

5. Atmospheric pressure:68~106kPa.

6. Gas supply: 5~8kg/ cm2.