The Significance and Challenges of Leak Detection

The Crucial Role of Leak Detection in Filter Products

In the manufacturing of filter products, leak detection is a fundamental process that directly impacts product quality and user safety. Filters are widely used in various industries, such as aerospace, automotive, and environmental protection, where even the smallest leakage can lead to severe consequences. For instance, in aerospace applications, a leaking filter in the fuel system may cause fuel loss, reducing engine efficiency and potentially leading to catastrophic failures. In environmental protection, a leaking air filter fails to block harmful particles, compromising air quality. Therefore, accurate leak detection is not only essential for ensuring product performance but also for safeguarding public safety and environmental sustainability.

Limitations of Traditional Leak Detection Methods

Traditional leak detection methods, including pressure testing and bubble detection, have inherent drawbacks in terms of positioning accuracy. Pressure testing involves applying pressure to the filter and measuring the pressure drop over time. However, this method only indicates the presence of a leak and cannot precisely locate where the leak occurs. Bubble detection, on the other hand, submerges the filter in a liquid and observes for bubble formation. While it can roughly identify the leakage area, it lacks the precision required for complex filter structures. These methods are often time-consuming, labor-intensive, and prone to human error, especially when dealing with small or irregularly shaped leaks.

Introduction to Filter Tester's Point-by-Point Scanning and Rescanning Technology

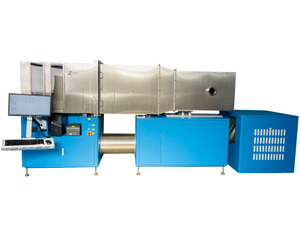

To overcome the limitations of traditional methods, Scince Purge Technology (Qingdao) Co., Ltd. has developed the Filter Tester, equipped with advanced point-by-point scanning and leak point rescanning technology. This innovative solution offers unparalleled precision in leak detection, enabling manufacturers to identify and localize leaks with exceptional accuracy. By combining these two technologies, the Filter Tester provides a comprehensive and reliable approach to leak detection, setting a new standard in the industry.

In-depth Analysis of Point-by-Point Scanning Technology

Explanation of the Point-by-Point Scanning Principle

The point-by-point scanning technology of the Filter Tester operates by systematically inspecting the entire surface of the filter product. The testing probe follows a pre-defined path, moving incrementally across the surface to collect data at each individual point. This method ensures that every part of the filter is thoroughly examined. The data collection frequency is optimized based on the product's size and complexity, typically ranging from several data points per millimeter to higher densities for more critical areas. The high-precision sensors on the probe are capable of detecting minute changes in parameters such as pressure, flow rate, and gas concentration, with an accuracy level of up to ±0.1% of the measured value.

Advantages of Comprehensive Coverage Detection

One of the key advantages of point-by-point scanning is its ability to eliminate detection blind spots. Unlike traditional methods that may miss leaks in hard-to-reach areas, this technology ensures complete coverage of the filter surface, regardless of its shape or structure. For complex-shaped filters, such as those with irregular curves or internal channels, the scanning path can be customized to adapt to the specific geometry, ensuring that all potential leakage points are inspected. This comprehensive approach significantly reduces the risk of undetected leaks, enhancing the overall reliability of the filter product.

Data Processing and Analysis

The Filter Tester's system is equipped with powerful data processing capabilities. As the probe collects data at each point, it is immediately transmitted to the central processing unit for real-time analysis. Advanced algorithms are employed to process the data stream, comparing the measured values against pre-set standards. These algorithms can quickly identify abnormal data patterns that indicate the presence of a leak. For example, a sudden drop in pressure or an abnormal increase in gas flow rate at a specific point can be accurately detected and flagged as a potential leakage point. The system's ability to analyze data in real-time enables immediate detection and response, improving the efficiency of the testing process.

Analysis of the Leak Point Rescanning Function

Trigger Mechanism of the Rescanning Function

The leak point rescanning function of the Filter Tester is triggered based on a set of predefined thresholds and logical rules. When the initial point-by-point scanning detects a potential leak, the system evaluates the reliability of the detection based on factors such as the magnitude of the parameter deviation and the consistency of the abnormal data. If the system determines that the detected leak requires further confirmation or more precise localization, it automatically initiates the rescanning process without any manual intervention. This intelligent triggering mechanism ensures that only significant and reliable leakage points are subject to rescanning, optimizing the testing efficiency.

Enhancement of Positioning Accuracy through Rescanning

During the rescanning process, the testing probe's movement trajectory is optimized to focus on the suspected leakage area. The system uses a more refined scanning pattern, reducing the step size between data collection points to achieve higher resolution. This allows for a more accurate determination of the leak point's exact location. Comparative data shows that without rescanning, the initial detection may have a positioning error of up to ±2mm, while after the rescanning process, the error can be reduced to within ±0.5mm. This significant improvement in accuracy is crucial for subsequent repair and quality control processes.

Capability to Capture Tiny Leak Points

The rescanning function of the Filter Tester is particularly effective in detecting tiny leak points, such as micro - scale cracks or pores. Its high - sensitivity sensors and refined scanning process enable it to identify leaks that are often undetectable by other devices. While traditional leak detection equipment may struggle to pick up leaks smaller than a certain size, the Filter Tester can accurately locate and measure leaks as small as a few micrometers in diameter. This capability is invaluable in industries where the integrity of filters is of utmost importance, ensuring that even the most minute defects are not overlooked.

Presentation of the Test Report and Leak Point Localization

Content and Format of the Test Report

The test report generated by the Filter Tester is comprehensive and detailed. It includes essential information such as the test time, product model and serial number, test parameters, and overall test results. The report also provides a breakdown of the data collected during the point-by-point scanning and rescanning processes. For leak detection, it clearly lists the suspected leakage points, their corresponding parameter values, and the confidence level of the detection. The report format is designed to be user-friendly, with a combination of text, tables, and graphical representations to present the information clearly and concisely.

Visualization of Leak Point Positions in the Report

To facilitate the understanding of leak point locations, the test report features advanced visualization techniques. Leak points are marked on a digital diagram of the filter product, with their coordinates clearly indicated. This visual representation allows technicians and engineers to quickly identify the exact position of the leaks on the filter surface. In addition, the report may include 3D renderings or cross-sectional views for more complex filter structures, providing a more intuitive understanding of the leakage situation.

Guiding Value of the Report for Maintenance

The detailed information provided in the test report is highly valuable for the maintenance and repair process. Maintenance personnel can use the report to precisely locate the leak points, reducing the time and effort required for troubleshooting. The clear presentation of parameter values and leakage details also helps in determining the appropriate repair methods. By having accurate information from the report, companies can minimize downtime, reduce repair costs, and improve the overall efficiency of their production and maintenance operations.

Conclusion

In conclusion, the point-by-point scanning and rescanning technologies of the Filter Tester offer significant advantages in leak detection. The point-by-point scanning ensures comprehensive inspection and accurate initial detection, while the rescanning function enhances the precision of leak point localization, especially for tiny leaks. The detailed test report, with its clear visualization of leak points, provides essential guidance for maintenance and repair. These features combined make the Filter Tester a highly reliable and efficient solution for ensuring the quality and integrity of filter products. For more information about this advanced technology and how it can benefit your business, please contact Scince Purge Technology (Qingdao) Co., Ltd.