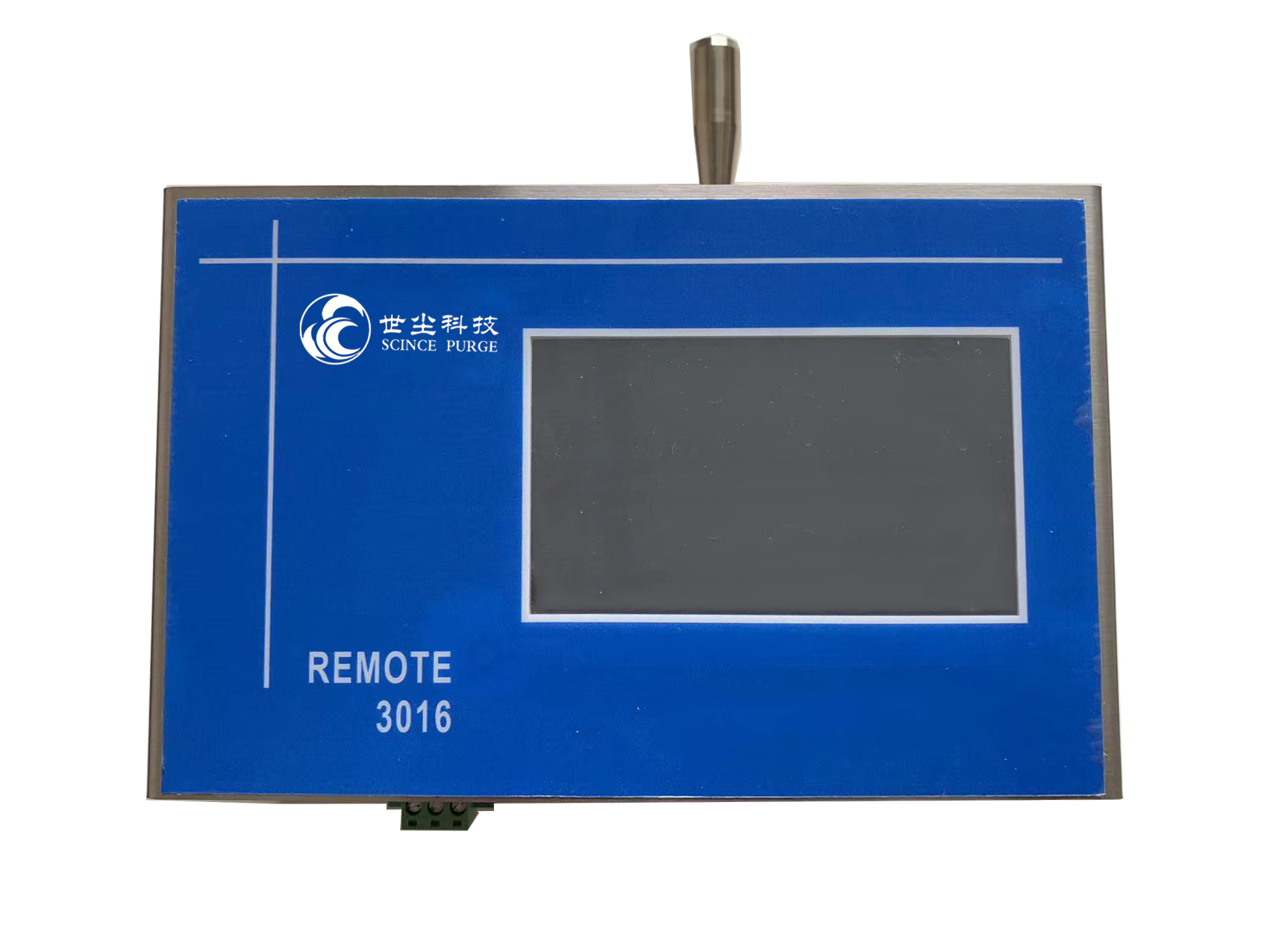

Advantages

The product conforms to GMP or ISO and standard of the clean room, it is safe and reliable.

24-hour real-time monitoring, real-time output of test results.

RJ45 interface is configured to facilitate connection with the bus. The built-in MAX1480E with optocoupler bus communication chip can ensure reliable communication transmission.

The particle counter has 6 particle size channels, all of which can be selected or two of which can be selected at random to meet different customer requirements.

Test results can be drawn as data curve, also can be generated as data report.

The monitoring data can be compared with the preset upper and lower limits of the data, and the audible and visual alarm can be alarm when the data is unqualified.

Application

It is used for real-time monitoring of particle concentration, temperature and humidity, pressure difference and wind speed at each monitoring point in the clean room. The monitoring data copper is sent to the monitoring software host through the switch, and the staff can view the status of each monitoring point on the host.

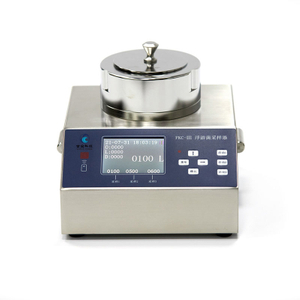

Main technical parameters

1. Sampling flow: 2.83 L/min.

2. Particle size channel: 6 channels, 0.3, 0.5, 1.0, 3.0, 5.0, 10.0μm。

3. Sampling period: 1~10000 s.

4. UCL setting: 2~9 sampling points, 2~9 sampling times per point, measurement position 0~999

5. Working time: 6 hours.